Roll paper machine

The single sheet feeding paper silk machine equipment is a device specifically designed to accurately and stably feed single sheet paper materials (which may include paper, cardboard, or other thin sheet materials) into subsequent processing equipment. This type of equipment has a wide range of applications in various industries such as printing, packaging, and paper processing.

| Dimension | 750*730*960MM |

| Weight | 190KG |

| Power | 1.5KW |

Product Principle

Startup and initialization: After the device is started, the control system performs initialization settings, including checking the status of each component, adjusting feeding parameters, etc.

Paper separation and transportation: The feeding system separates individual sheets of paper from the stack of paper through mechanical or pneumatic means and transports them along a predetermined path to the processing area. During this process, the adjustment mechanism will adjust the position and angle of the paper as required.

Precise control: The control system precisely controls the action speed and timing of the feeding system based on the demand signals of the processing equipment, ensuring that the paper can enter the processing area accurately and without error.

Security protection: Throughout the entire process, the security protection device will continuously monitor the status of the equipment. Once any abnormal situation is detected (such as paper blockage, equipment failure, etc.), protective measures will be immediately triggered and an alarm will be issued.

Product Application

Improve production efficiency: Automated feeding systems can significantly reduce manual intervention and waiting time, improving the overall efficiency of the production line.

Ensure product quality: Accurate feeding control and adjustment mechanism can ensure that each paper can enter the processing equipment accurately and without error, thereby avoiding product defects and waste.

Reduce labor intensity: Automated operations reduce workers’ physical labor and repetitive workload, improving the comfort of the working environment.

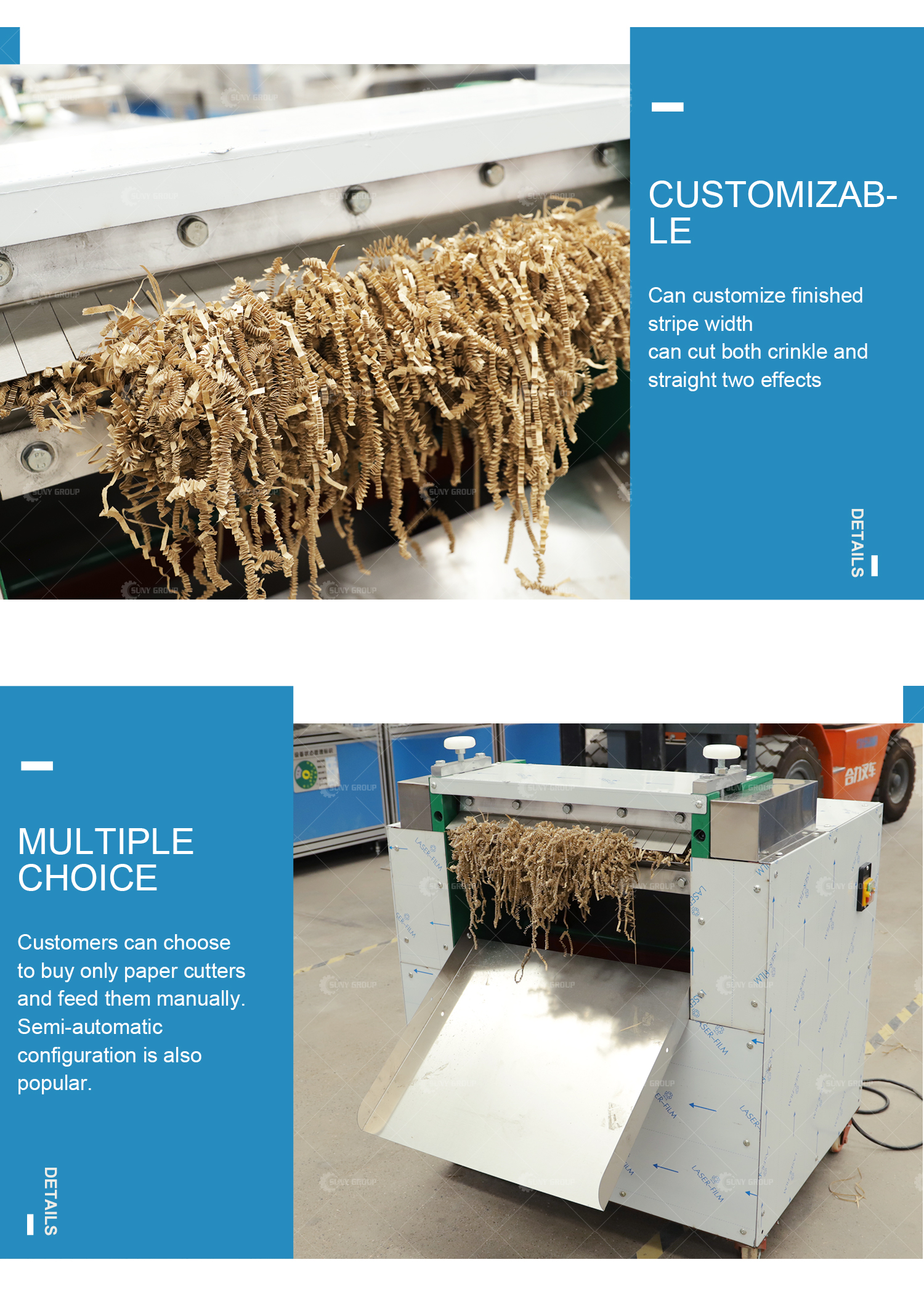

Enhance flexibility: Feeding paper wire machines usually have multiple feeding modes and adjustment functions, which can adapt to the processing needs of different specifications and materials of paper.